Inspired by the global success stories of modular off-site construction, we presented the country with a new agile and more productive construction system which, by achieving better finishes, redounds to benefits for users. This disruptive proposal is part of our constant search for deliver extraordinary solutions to our clients that contribute to the industrialization of the sector, while contributing to closing equity gaps and promotion of decent housing.

The modular system of panels in particular allows reduce project construction times by up to 40%, significantly improving the overall productivity of a work. Likewise, the efficiency of the system allows better integration of the construction, sales and delivery cycles of homes, which benefits both builders and users.

“Our motivation to present this innovation of concrete modules to the market is to seek, together with the builders, processes to improve productivity and greater efficiencies. In addition, thanks to the geometry and the finishes with which the elements remain, the homes are more comfortable and Colombians who access this type of building enjoy better homes, thus we create social value. We can compare this innovation with some chips, in this case panels, which are assembled on site ”.

Thomas Restrepo. Vice President of the Argos Colombia Regional.

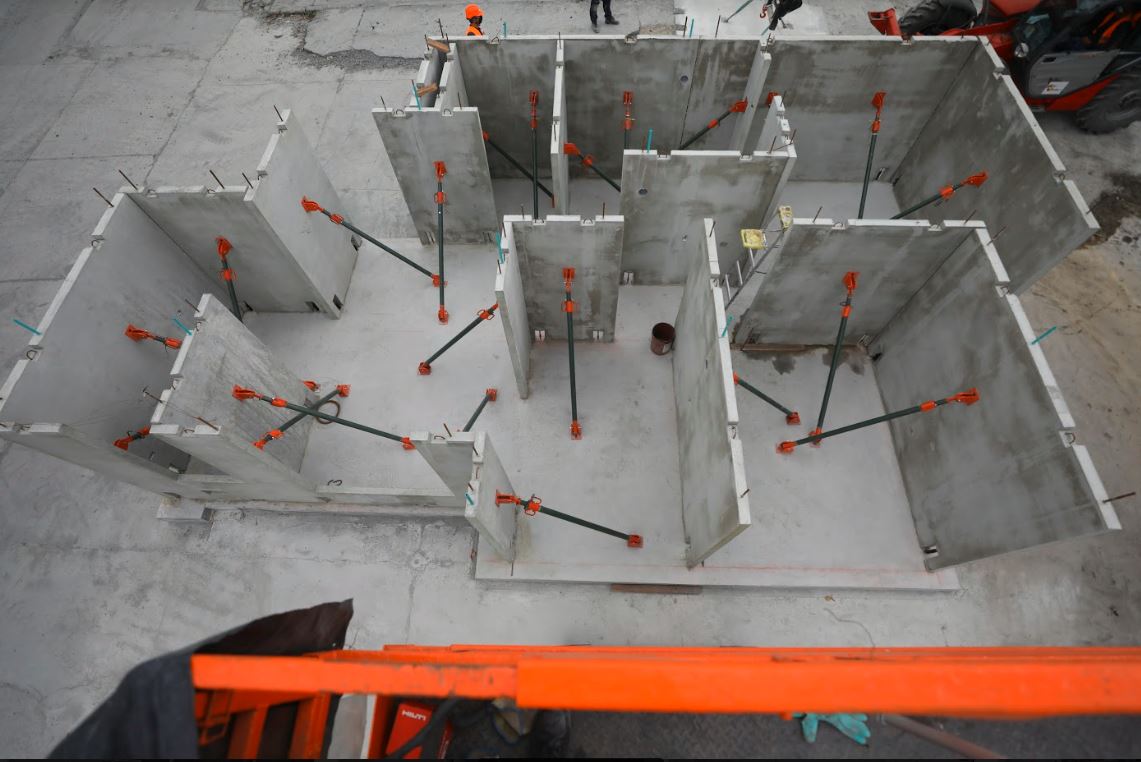

With this alternative, we expand our portfolio of products and services with a comprehensive solution for modular design, production, transportation and on-site assembly of modules specifically for buildings. In this way, our clients can focus efforts on other relevant aspects of the construction process, while we provide our experience and technical advice throughout the cycle of the building structure.

One of the main differences with the traditional system is that the manufacturing of the building is transferred to a production plant and, with this, the risks and the amount of externalities to which a construction project is subject are reduced, such as, for example , weather conditions.

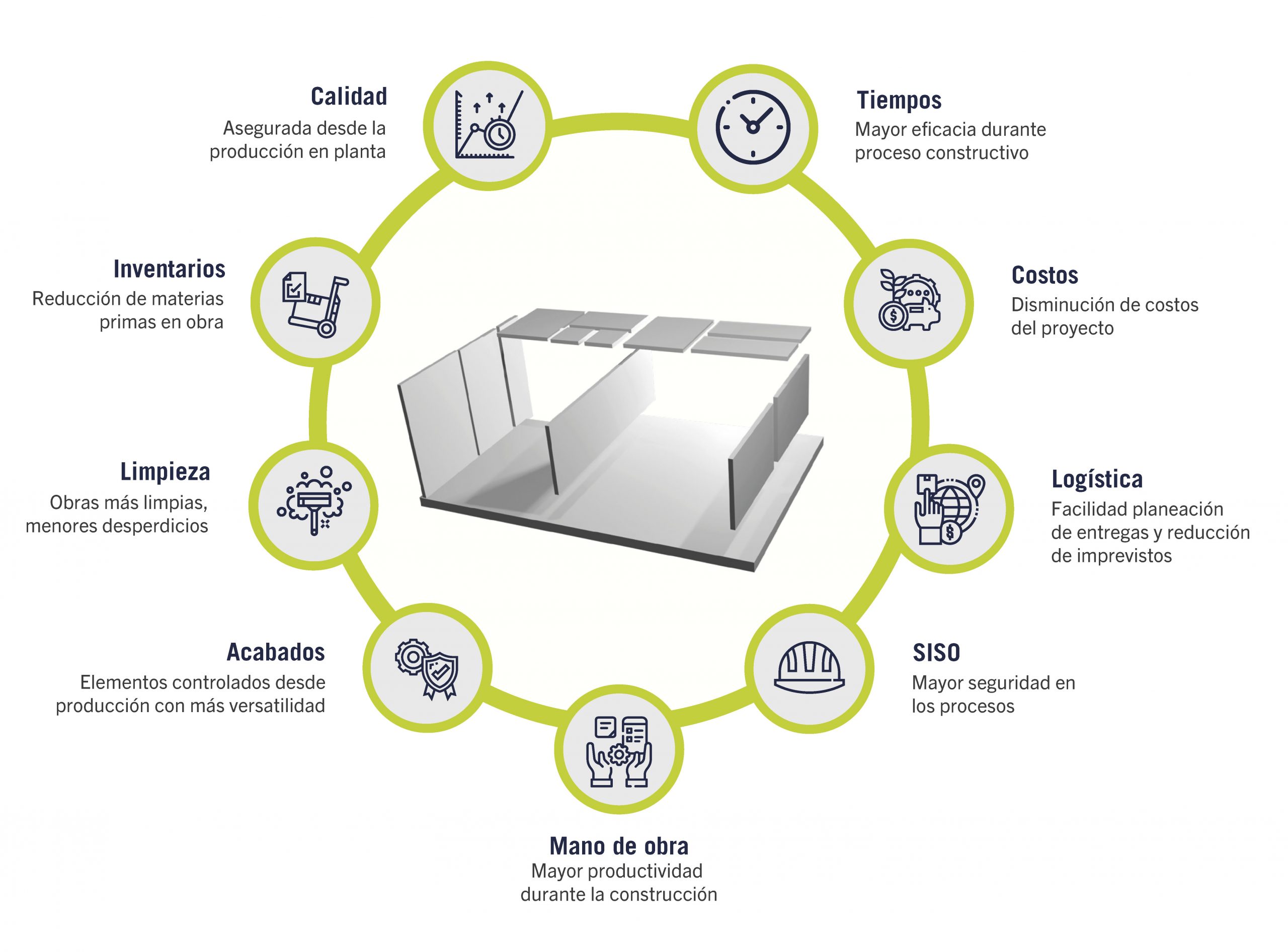

Being able to move the construction to the controlled environment of a production plant allows reducing the amount of waste, improving sustainability practices, minimizing material inventories and easing administrative processes. Among others, these are the great benefits of using the modular panel system in particular:

Countries that have managed to break the productivity barrier in construction have done so through off-site construction processes, such as Japan, China or the Scandinavian countries. In addition, in countries such as Singapore, the United Kingdom and the United States, public policies have been implemented to favor these construction systems and that households have access to higher quality housing.

This construction practice, more industrialized, efficient and technological, can be applied in all building and infrastructure segments. However, this new line of business is initially focused on the construction of affordable housing.